QUALITY STANDARDS:

ISO 9001-2015

UKRBIOTAL meets international quality management standards.

BIOTAL SYSTEMS have been manufactured since 2000. The company has a strong reputation in the field of wastewater treatment worldwide. The main business principle of the company is to provide customers with sewerage system, commissioning and delivery.

WORK PRICIPLE :

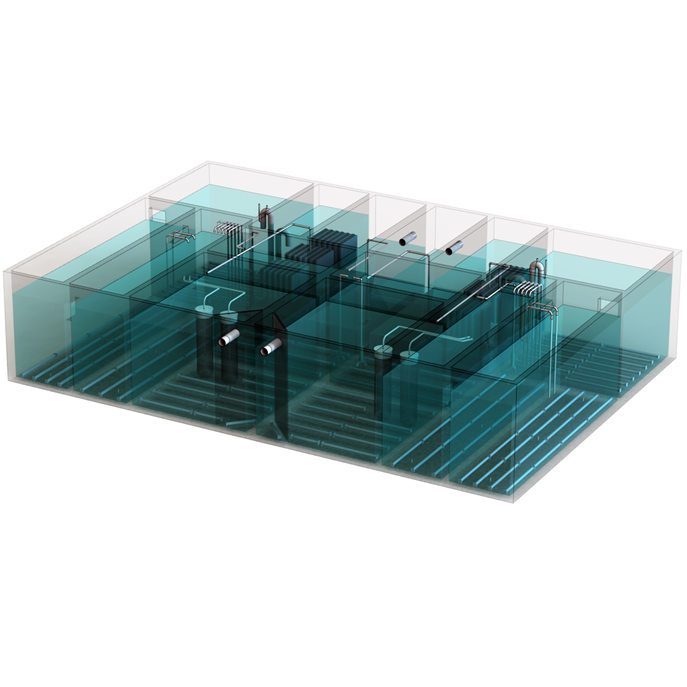

In SBR-1, the wastewater discharges into the SBR-2 chamber. Reversive cooling here as well

As a result, the foam flows, which removes the SBR-3 from the negative effects of saponates. Where in the

SBR

As with the SBR-2, the sludge mixture is repeatedly subjected to aerating and mixing.

Partially treated sewage flows from SBR-2 to SBR-3 and reaches SBR-1 and 2 as a result of reversible cooling.

collect masses to generate backflows. Oxidation of a highly oxidizing organism in SBR-3 and

nitrite occurs. At this stage, the sludge mixture collapses after exposure to aerosol. Prior to the purification

of the treated sewage from the SBR, an excess of active sludge is filled with aerobic stabilizer (8). Water

from the stabilizer to the drying unit is transferred to the SBR-2. After the deposition process at SBR-3 and

the removal of excess sludge, the treated water is transferred to the biological filter from the SBR-3 and the

final treatment of the water takes place. The SBR-3 purified wastewater is pumped to the bottom of the

biological filter (6) and the excess of the water in the filter

moves the treated water from the bottom up. Plastic sheets inside the filter hold all the small particles with

high efficiency. The fully treated water will be discharged and discharged from the system.

⦁ 1) Reception Network

⦁ 2) Generator

⦁ 3) Air fridge

⦁ 4) Revers air cooler

⦁ 5) Siphon _p air cooler

⦁ 6) Tertiary Deposition Division

⦁ 7) Silt bags

⦁ 8) Aerobic stabilizer of lily

⦁ 9) Circulation-type biological filter

Even in the case of power cuts, high cleaning results in efficiency. When the amount of wasted water enters

the system, the system enters the 1st (1 hour), the second (after 24 hours), the 3rd (after 168 hours), and

saves up to 70% of electricity. . The life of electrical equipment is prolonged, and the operation mode is not

broken when long wastewater is not entered into the system. In addition to the save mode, the system

switches to an accelerated operation mode when there is a large volume of wastewater that can run up to

25% of the daily rate.

Cleaning process management is fully automated and has service staff

All elements of the system are easily disassembled and allow servicing without disturbing the operating

mode.

The equipment beeps when equipment fails or the cameras are caught for some reason.

As a result of the cleaning process, technical water and solid sludge are obtained. These products can be

used safely, such as irrigation and fertilizer.

As a result of the use of modern technology and equipment of high quality manufacturers, the biotech

works reliably and economically. Electrical parts MOELLER Germany, compressor ELMO RETSCHLE Germany,

NITTO SECOH Japan, electromagnetic grinders ASCO Netherlands and others.

Kuryer xidməti PULSUZ

Quraşdırılma xidməti HƏDİYYƏ